Blog

Shading the pilgrimage route, Mina, Saudi Arabia

Our office has been commissioned to design the shading of the religious pilgrimage route linking Mount Arafat to Mecca in Mina, Saudi Arabia. The primary aim of the investment was to make the long and arduous walk more comfortable for the pilgrims. We had to design the shading in a way that local contractors could build a timeless system as easily and accurately as possible.

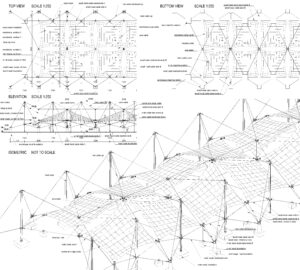

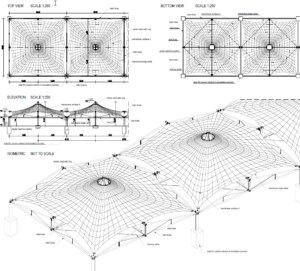

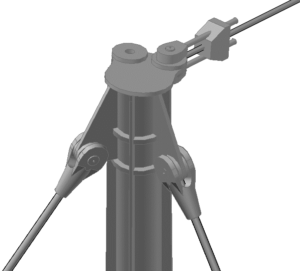

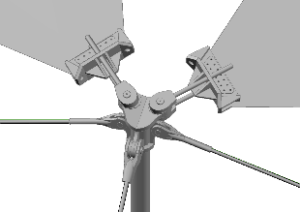

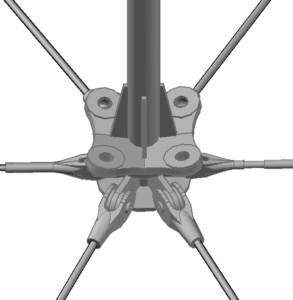

The site is huge in architectural scale; we designed nearly 600,000 square metres of shading over the 30m wide and 20 km long pilgrimage route. Studio IN-EX is responsible for the architecture and the design coordination of this unconventional design project, which also had to meet local needs. The structural design was led by Dr. Dezső Hegyi, a renowned designer, espacially in the field of tent and membrane structures. The biggest challenge for us was to create a typified system of mostly uniform elements that could be easily assembled on site, along the entire length of the road, adapting to the changing environmental conditions – junctions, bends with different angles, tunnels, bridges, roadside rocks, landmarks. The solution was found in a membrane system stretched on a steel frame structure on masts, with uniform elements that can be prefabricated and easily constructed on each section of the road, based on easy-to-understand installation drawings.

In line with the construction schedule, the area was divided into zones corresponding to the construction phases. In addition to the zones, economic feasibility was also an important objective, so we aimed to ensure that each module could stand on its own without the need to double the supporting columns and beams. We designed the system with as few different types of elements as possible, so we ended up with 2 main module units, which could cover the whole distance complemented by a few individual elements in specific locations.

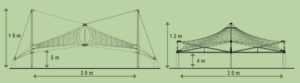

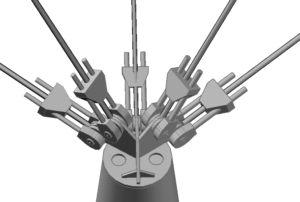

On the general, the desert section of the road, we chose a solution without internal supports, which does not impede the free flow of pilgrims. Since the repetitive module sizes had to cover large spans (30x30m), this was solved by “tying” the structure to the side, using so-called tieback anchoring. In urban areas, where anchoring was not possible due to space constraints, but the faster flow of the uprushing mass required the use of lanes, we provided support by using central columns.

In these sections, two 15-metre-wide flow zones (equivalent to about 5 traffic lanes) were created with barriers in the middle or fences.

All the elements of the steel structures, their foundations and anchorages were specified based on detailed drawings and schedules. The spatially curved awning elements were created using special software, according to a 3D pattern.

In addition to shading, the concept also included the installation of humidification systems under the tents and the upgrading of some roadside sanitary blocks. The designing process itself took several months: it started with the detailed geodetic survey of the road and its surroundings and ended with the construction designs, including the product drawings.

We are proud to have been part of such an internationally unique and large-scale project.

Author: Péter Gáti, stúdió leader

Recent posts

Hydro Extrusion – Office with a Minimalist Design

Hydro Extrusion Hungary Kft. is a subsidiary of a Norwegian parent company, so an important aspect of the interior design process was to ensure that the minimalist aesthetic and the company’s brand colors are harmoniously reflected throughout the interior spaces.

Professional day for students of civil engineering

Students from Zielinski Szilárd College of Civil Engineering have just participated in an exciting professional visit to the STUDIO IN-EX general design office.

Final exams at the BME

Thanks to the Faculty of Civil Engineering, Zsolt Oláh was invited to be an external committee member for the MSc in MSc in Construction Information Technology Engineering to review the students' thesis and attend their final exams.

Hydro Extrusion’s solutions: heat dissipation

By Hydro's aluminium foundry project presented us with an unusual design challenge. We have strong acoustic requirements to protect the neighbourhood, and that the furnaces generate a lot of heat, which we had to dissipate while minimising noise.

Hydro Extrusion’s solutions for the support structure

In our previous posts, we introduced you to our Hydro project and the design of the casting pits that form the backbone of the technology. This time we present some exciting solutions for the support structure.

Engineering and what lies behind it

A special career orientation day has allowed students at Petőfi Sándor Gimnázium to get a glimpse of a career in engineering.