Blog

Hydro Extrusion’s aluminium recycling plant: the casting pits

We have previously reported on the general outlines of our Hydro aluminium foundry project in Székesfehérvár. By focusing on the designing process and the aspect of civil engineering, now we would like to briefly present the most interesting part of the technology, namely the casting pits.

During the casting process, the molten aluminium is cleaned of dissolved gases and other physical impurities, and the molten metal is then fed through channels to one of two casting stations. During the crystallising process, heat is removed here by cooling water to create the circular aluminium ingots.

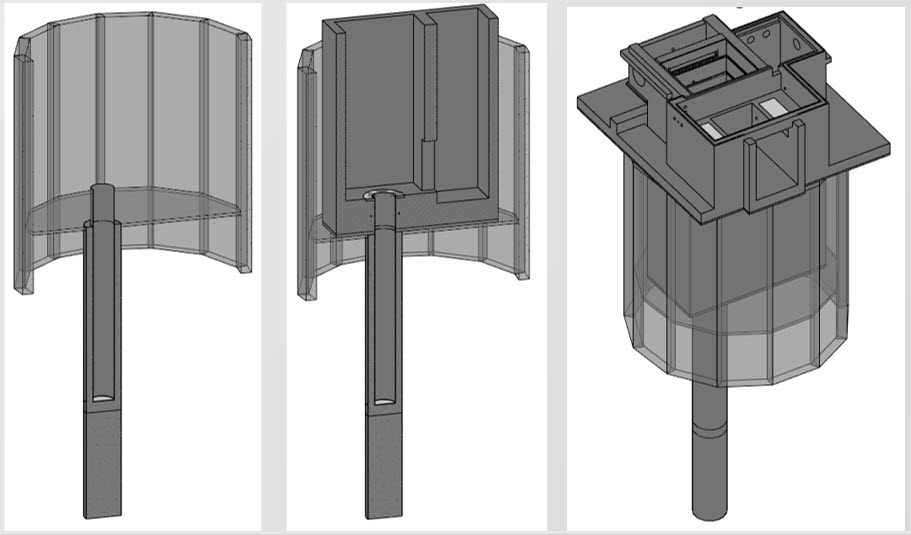

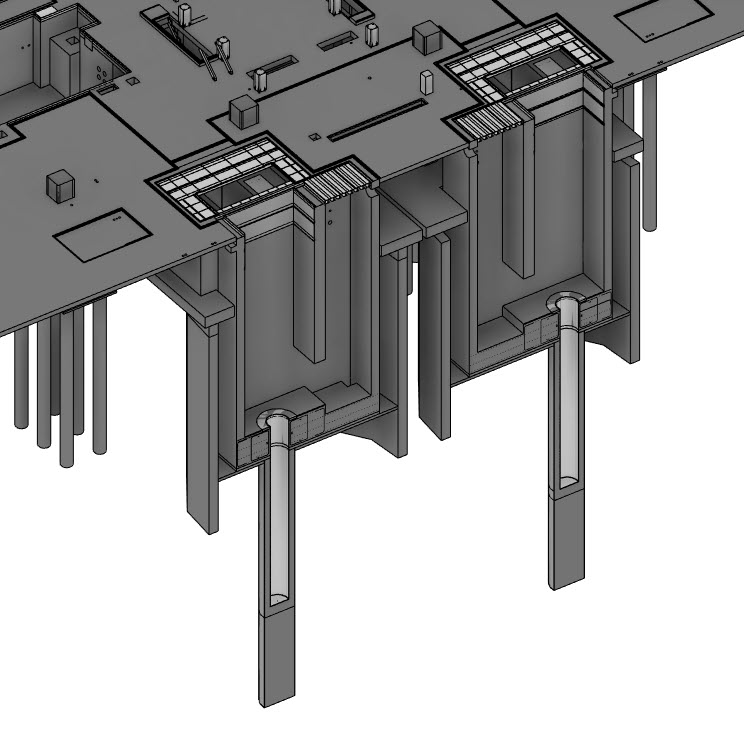

This process is served by the two casting pits, which are made up of the following units from bottom to top: between -25 m and -12 m, the hydraulic working cylinder of the casting table is housed in a closed steel tube with a diameter of 1.10 m, which is fixed by concrete lining in an external steel tube with a diameter of 1.80 m. The outer pipe was required to contain the working area and was inserted into a 2.00 m diameter drill hole, followed by 5.00 m of concrete backfill with slurry support to prevent floating and finally the concrete-lined “utility pipe” to contain the working cylinder.

This structure is connected 12 metres below ground level via a 1.65m-thick base plate to the casting pits, in which the casting tables used for casting can move. During the casting process, these are gradually lowered into the cooling water pit and the solidified aluminium billets are then lifted so that they can be lifted out by using a crane. The challenge was also that the temperature of the cooling water can be as high as 60°C, and the whole structure stands 5-7 m above this, while dust dryness requirements were specified for the casting pits. This is to ensure that the process water does not contaminate the environment and that the groundwater cannot contaminate the aluminium. In addition to this, another challenge was the fact that the lifting of the tray can generate a moment of up to 1700 kN/m, which the technology transfers to the base plate through a 2.00 m diameter, 110 mm thick steel disc, which had to be positioned with millimetre tolerances during the iron assembly.

millimetre tolerances during the iron assembly. Due to the complexity of the task, the reinforcement of the base plate and the disc were 3D-reinforced to minimise problems during construction. We also had to coordinate all this with the furnace shafts between the floor line and -4m, and with the mechanical and electrical wiring designed by the technologist, during which 35 watertight breakthroughs were individually designed as detailed as possible, just for the casting pits. The entire process is completed by a cooling basin and a water tower outside, which circulate the water in a closed system, so that only the loss occurring during evaporation needs to be filled up in the process.

In the following posts, we will also present other challenges regarding the supporting structure and the ventilation of the building, which presented us with similar difficulties as the casting pits.

If you have missed our previous article, find it here: Hydro Extrusion’s new aluminium recycling plant

Dániel Dobszai, Dávid Mészáros, Kamilla Zámbó, architects

Recent posts

Final exams at the BME

Thanks to the Faculty of Civil Engineering, Zsolt Oláh was invited to be an external committee member for the MSc in Building Information Engineering to review the students' theses and attend their final exams.

Hydro Extrusion’s solutions: heat dissipation

By Hydro's aluminium foundry project presented us with an unusual design challenge. We have strong acoustic requirements to protect the neighbourhood, and that the furnaces generate a lot of heat, which we had to dissipate while minimising noise.

Hydro Extrusion’s solutions for the support structure

In our previous posts, we introduced you to our Hydro project and the design of the casting pits that form the backbone of the technology. This time we present some exciting solutions for the support structure.

Engineering and what lies behind it

A special career orientation day has allowed students at Petőfi Sándor Gimnázium to get a glimpse of a career in engineering.

Visiting a factory building site at the beginning of your professional career

The construction of several buildings of our Nyíregyháza-based project is at such a stage that the electrical team, together with the BMS team, decided it would be worth taking a look at the work in progress.

We support the career choices of future engineers!

Since autumn 2024, our company has been an active member of the association "Together for Future Engineers" (EJMSZ).