Blog

Automating AHU Family Creation

In the realm of engineering solutions, STUDIO IN-EX takes pride in providing practical innovations that simplify complex processes. Our collaboration with Rosenberg Gmbh exemplifies our dedication to delivering customized solutions that enhance the efficiency of Air Handling Unit (AHU) design for mechanical engineers. Through careful planning and expertise, we’ve crafted a tailored tool that simplifies the integration of AHU designer software with Revit content, easing the workload for mechanical engineers collaborating with Rosenberg Gmbh.

Tasked with the challenge of creating a seamless link between their AHU designer software and Revit content, we aimed to reduce the manual efforts of mechanical engineers in recreating equipment from 2D drawings. AHUs are inherently diverse and project-specific, necessitating an approach that streamlines the design process. Departing from traditional methods where engineers manually recreate equipment from 2D drawings in Revit, our tool automates the generation of dynamic Revit Families from the AHU designer software, minimizing the workload for mechanical engineers.

Our journey began with a deep understanding of Rosenberg’s AHU designer software. We developed a tool that assembles component families intelligently, setting their parameters to create the output family. This dynamic approach ensures the tool adapts to the specific requirements of each project, maintaining consistency and precision in every generated Revit Family.

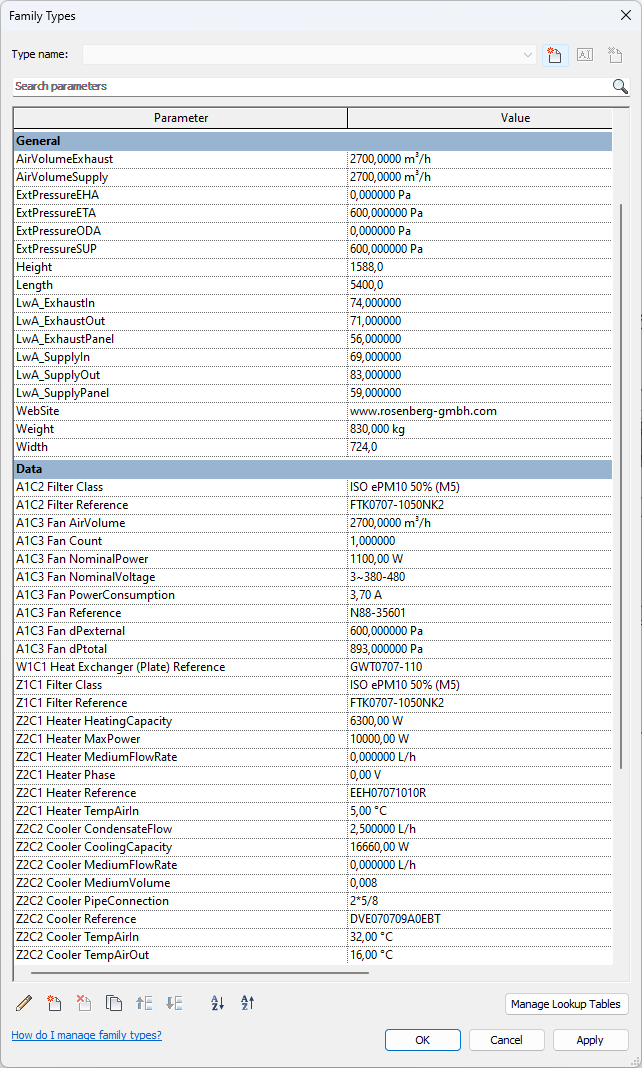

The families generated by our tool encompass a comprehensive range of components, including housing modules, symbols for internal components, duct connector frames, rain protection hoods, grilles, and optional raincover roofs for outdoor placements. Our solution also incorporates pipe and electrical connectors with precise sizes and flow data, alongside a variety of parameters essential for informed engineering decisions.

Recognizing the potential challenges of shared parameters, we opted for Family Parameters to grant mechanical engineers flexibility and control without compromising project integrity. These parameters can easily be converted into shared ones, allowing engineers the freedom to schedule or tag elements based on project requirements.

As the project progressed, we took a significant step towards efficiency by developing an advanced service. This service, operational on a server, autonomously monitors an input folder where data files are automatically exported by the AHU designer software. When a new file is detected, the service triggers the conversion process, generating the Revit Family and a corresponding screenshot in a predetermined output folder. This automation eliminates the need for manual intervention, providing Rosenberg’s staff with a seamless, hassle-free experience.

The success of our collaboration with Rosenberg Gmbh is reflected in the efficient delivery of results. Studio IN-EX has met and exceeded expectations, providing a solution that prioritizes simplicity and efficiency in AHU design for the collaborating mechanical engineers. Our dedication to practical innovation sets a new standard, and we look forward to continuing our journey as partners in enhancing engineering workflows.

At STUDIO IN-EX, we thrive on custom software development challenges within the AEC industry. Our expertise extends beyond AHU design to a wide array of tailored solutions. We welcome organizations seeking innovative, bespoke tools to enhance their workflows. Explore the possibilities with STUDIO IN-EX, where we transform unique requirements into efficient, cutting-edge solutions. Connect with us to embark on a journey of collaborative custom development that reshapes the landscape of the AEC industry.

Author: Tamás Déri, Deputy BIM Studio Leader

Recent posts

Final exams at the BME

Thanks to the Faculty of Civil Engineering, Zsolt Oláh was invited to be an external committee member for the MSc in Building Information Engineering to review the students' theses and attend their final exams.

Hydro Extrusion’s solutions: heat dissipation

By Hydro's aluminium foundry project presented us with an unusual design challenge. We have strong acoustic requirements to protect the neighbourhood, and that the furnaces generate a lot of heat, which we had to dissipate while minimising noise.

Hydro Extrusion’s solutions for the support structure

In our previous posts, we introduced you to our Hydro project and the design of the casting pits that form the backbone of the technology. This time we present some exciting solutions for the support structure.

Engineering and what lies behind it

A special career orientation day has allowed students at Petőfi Sándor Gimnázium to get a glimpse of a career in engineering.

Visiting a factory building site at the beginning of your professional career

The construction of several buildings of our Nyíregyháza-based project is at such a stage that the electrical team, together with the BMS team, decided it would be worth taking a look at the work in progress.

We support the career choices of future engineers!

Since autumn 2024, our company has been an active member of the association "Together for Future Engineers" (EJMSZ).